Lonypack: Optimizing food packaging with 3D printing

Lonypack Global has 25 years of experience in the canned meat and dairy sector. An hour's drive northwest of Madrid, Spain – it has received the highest standards in certification for its deboning, slicing and packaging lines at its plant.

In early 2022, after consulting with Sicnova, Lonypack decided to incorporate 3D technology in its plant to optimize the production process, using UltiMaker 3D printers and 3D printing materials from Kimya.

Achieving greater self-sufficiency and cost savings

Lonypack began researching 3D printing in early 2022. Their goal was to develop new component designs that would optimize the manufacturing process. This would allow the Spanish company to achieve these improvements in its state-of-the-art plant in the most economical and customizable way possible.

The first challenge was sourcing production materials that are safe for food contact. To increase self-sufficiency and durability, Lonypack needed a way to regain control of the supply of spare parts and the production of components for its boning, slicing and packaging lines.

3D printing has allowed us to create parts such as cutting edges, picking combs, turning mechanisms and gears for our robotic arms and knives at up to 70% less.

– Román Velasco, Director of Industrial Engineering at Lonypack.

Food safe parts printed with Kimya PETG-S filament

Lonypack began looking at using UltiMaker S5 3D printers to create custom parts for its production line. To do this, they followed the advice of Sicnova and its distributor Cosomo 3D, who supported them throughout the process of implementing the technology.

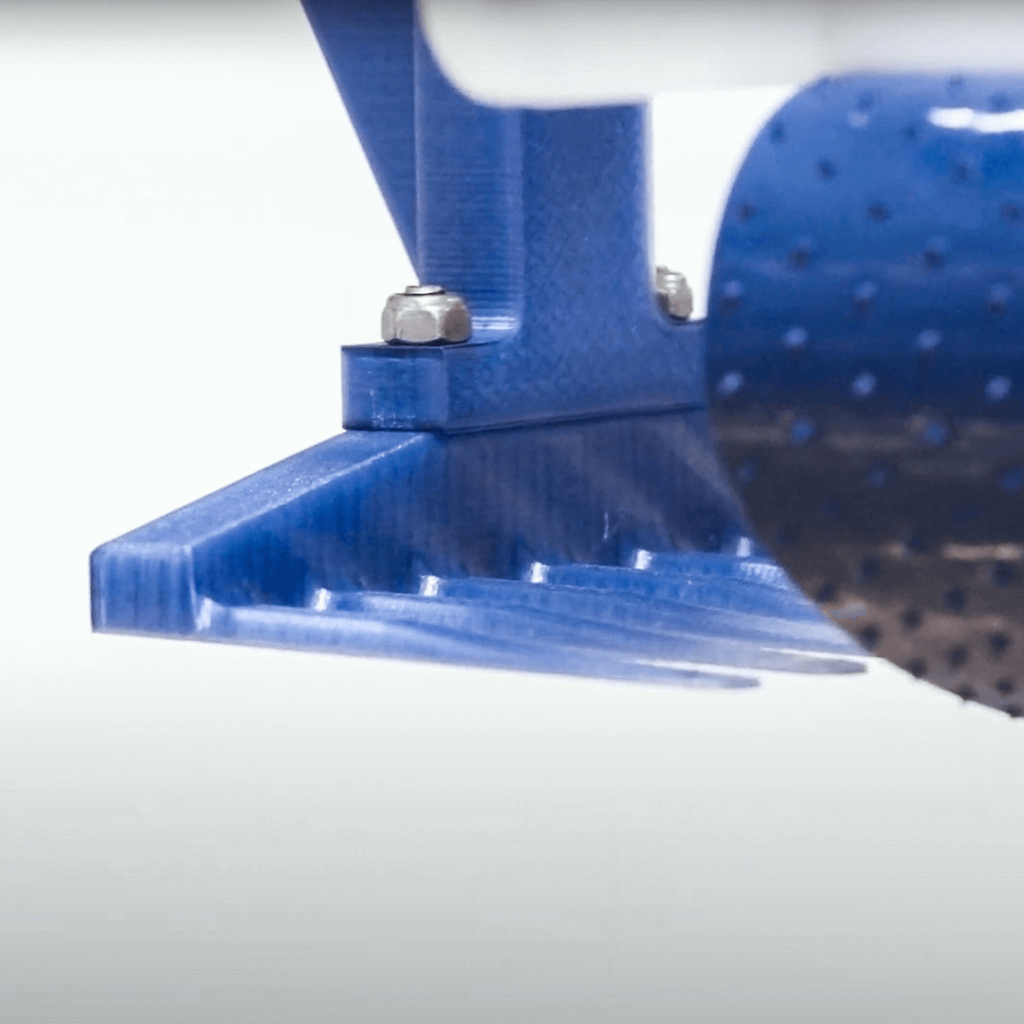

The precision and reliability of the UltiMaker S5, a machine that brings industrial capacity to desktop size, was the reason Lonypack chose this model. In addition, they chose PETG-S filament from leading materials brand Kimya because it is certified as food contact safe, as evidenced by its blue color.

70% parts savings and reduced lead time

New design solutions were implemented from the very beginning. Lonypack has created parts, including cutting edges, comb-type gathering tools, rotary mechanisms and gears, costing up to 70% less than they were used to before.

Delivery times were also reduced with the 70% compared to the deliveries they were getting before.

Cutting edges protect the blades during cutting. Picking combs pick up the portions to be bagged. And the turning mechanism transports the portions to empty trays that are part of the package. None of these savings in robot arm and cutter labor would be possible without Kimya's guarantee that printed parts are food safe throughout the process.

Wider acceptance in the food industry

Lonypack's first attempt at 3D printing was a great success, as Román Velasco explains:

"It is only a matter of time before other food companies implement these solutions in their production processes. And in the future, they will be an essential part of factories."

0 Comments